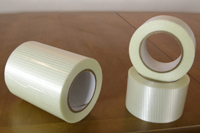

Bi-filament Tape Specs Explained

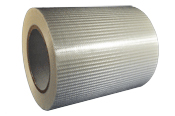

The “Bi” in bi-filament tape is short for “bi-directional”. That is a reference to the two different filaments in the tape that run at right angles to each other. These filaments both give the tape its strength and its ability to resist stretching.

The “Bi” in bi-filament tape is short for “bi-directional”. That is a reference to the two different filaments in the tape that run at right angles to each other. These filaments both give the tape its strength and its ability to resist stretching.

Both characteristics are critical to seaming the panels of a hexahurt.

The filaments are made from polypropylene and have a fiberglass reinforcement to resist tearing.

The combination of two separate filaments running in two different directions create what is called tensile strength. Tensile strength is a way of measuring how much force is needed to tear the tape. The tensile strength of bi-filament tape is 220 lbs, meaning that a force equivalent to at least 220 lbs. is required to tear it.

This tape uses a highly aggressive rubber adhesive, which gives it great holding power. The holding power is measured posted in a measurement called adhesion to steel, which is the force necessary to pull the tape from a piece of stainless steel. In this case, at least 91 lbs of pulling force is necessary to remove the tape.

This product, which was originally created for industrial palletizing, strapping and bundling, has unique qualities that make it a “must have” for hexayurt builders.